Libramiento Oscar Flores Tapia #1038 Int 3 y 4 Fracc. Presas de las casas C.P. 25369 Arteaga, Coahila, México

Libramiento Oscar Flores Tapia #1038 Int 3 y 4 Fracc. Presas de las casas C.P. 25369 Arteaga, Coahila, México

We are the right choice, a one stop source with 10+ years of process production engineering with the most competitive prices and quality solutions for every single one of our clients.

Download our presentation

Mechanical & Electrical Design

Hardware

HardwareSelection

Software

SoftwareDevelopment

3D CAD

3D CADSoftware Planning & Design

AutoCAD

AutoCADMachining Capabilities

We have the best tools and

equipment on the market

for your needs

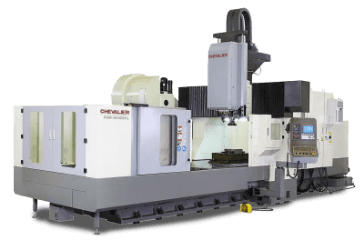

Chevalier FVM-3016DCL

Payload : 6,500 kg

Capacity: X/Y/Z

(mm): 3,100 x 1,600 x 780

Haas Mini Mill

7.5 hp

5.6 kw

6000 rpm

16 x 12 x 10’ ’

406 x 305 x 254 mm

Titanium CK7130BP

Máx. turning diameter (mm): 350

Slide stroke X-axis (mm): 350

Paso de barra (mm): 36

Mitsubishi Wire EDM

15.7 x 1 1.8 x 8.7’ ’

400 x 300 x 220 mm

Wire Diameter Possible: 0.004-0.012 mm

Minimum Start Hole Diameter: 0.02 mm

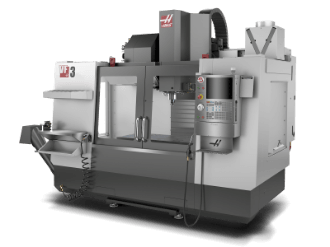

Haas VF-3

30 hp

22.4 kw

8100 rpm

40 x 20 x 25’

116 x 508 x 635 mm

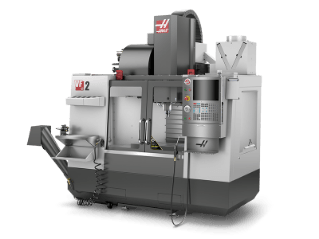

Haas VF-2

30 hp

22.4 kw

8100 rpm

30 x 20 x 25’

762 x 508 x 635 mm

Why FX2?

Because we’re the leaders on oering a complete solution to your project, working with creativitye, flexibility, adaptability and skilled people.Our Facilities

HERMOSILLO, SONORA

64,600 ft² (6,000 m²)

Land Main Offce

14,650 ft² (1,361 m² )

Assembly Area

Inspection and Quality

SALTILLO, COAHUILA

Office and special

equipment facility.

Controls & Robotics:

6460 ft2 Land

•Controls •Robotics •PLC

•Software Planning and Design

•Software programming

PUEBLA

Sales Office

Full Machine Shop

6460 ft2 Land

•Controls •Robotics •PLC

•Software Planning and Design

•Software programming

Automatic Cells Products

Integration Systems Portafolio

Spot Welding

MIG Welding

Vision Systems

Bushing

Clinching, Piercing

and Riveting

Adhesive Equipment

Laser Cutting

and Engraving

Project Process & Standard Timing

Our Advantage

- Expertise from drawing to integration.

- Fast answer at your requirements.

- Qualify and experience people to warranty the results.

- Best solutions.

- One stop shopping solution with 10+ years of process production engineering with a very competitive cost.

- Extensive background for ergonomics tooling specialized on High Tech and low cost tooling solutions.

Contact Us

Get In Touch

Libramiento Oscar Flores Tapia #1038 Int 3 y 4 Fracc. Presas de las casas C.P. 25369 Arteaga, Coahila, México

Libramiento Oscar Flores Tapia #1038 Int 3 y 4 Fracc. Presas de las casas C.P. 25369 Arteaga, Coahila, México

(+52) 844 869 22 06

(+52) 844 869 22 06